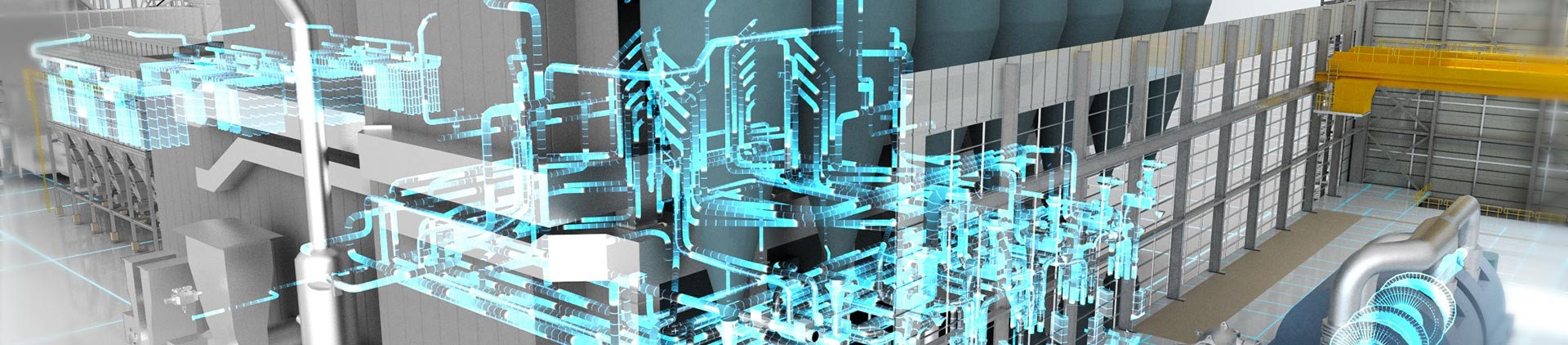

Our balance of plant expertise covers all supporting and auxiliary equipment with solutions tailored to individual power plant's needs.

Performance, reliability and lifetime extension

With decades of balance of plant expertise ranging from optimisation and engineering studies to repairs and the supply of spare parts, our team ensures all power plant components continue to run efficiently. Our fully integrated service covers mechanical and electrical equipment as well as pressure parts and condenser tube cleaning methods (formerly known as Technos).

Heat exchangers

- Moisture Separator Reheaters

- Condensers

-

Deaerators and feedwater heating equipment

incl. HP & LP Heaters

Mechanical

- Delas’ Check Valves and more

- Vacuum systems

- Metallic and Elastomer expansion joints

-

Mechanical components incl. bolts, filter,

gaskets, spray nozzles etc.

Electrical and I&C

- Network 6.6kV and 24kV, switchboards etc.

- DCS Module, 9020

- Low voltage components, transformers, chargers

- Instrumentation

Technos, Condenser Cleaning System (CTCS)

- Rubber balls

- Condenser tubes antivibration laths

- Debris filter

- Various parts

Balance of plant service solutions

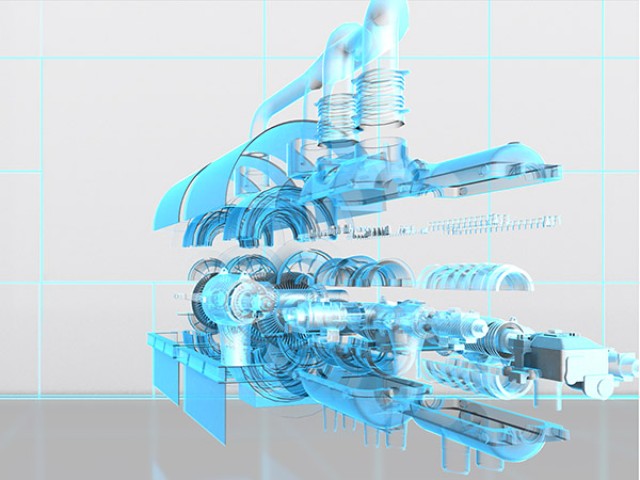

Upgrades, retrofits, replacements and more

Our extensive heat exchanger capabilities and expertise range from inspections, lifetime and performance assessments to upgrades, retrofits and replacements as well as retubing, refurbishment and repairs.

We can also provide a comprehensive view of the condition of your heat exchangers, identifying potential issues and propose preventive maintenance as well as review operations and reliability.

Condenser tube cleaning systems

Our automatic condenser tube cleaning methods (formerly known as Technos solutions), help to maintain power plant efficiency. Arabelle Solutions can deliver a tailored solution that meets your needs.

Benefits of employing a condenser tube cleaning system include:

- Maintain condenser performance

- Continuously clean an operating unit—with no shutdown

- Works without any chemical treatment

- No environmental impact

High and low voltage equipment

All our electrical work and equipment is completed and certified according to the IEEE nuclear power plant standard.

From transformers and circuit breakers to relays and cable, our expert team has the training and experience to ensure your high voltage equipment remains safe and reliable. Our low-voltage service covers everything from fire detections and alarms to control rooms and switchboards.

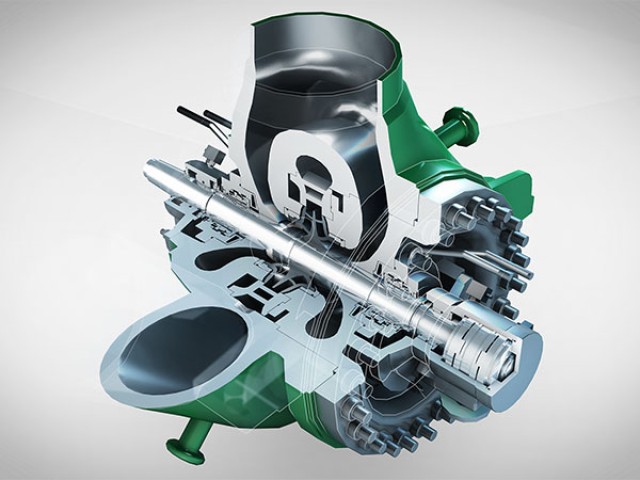

All mechanical auxiliary components

Our mechanical balance of plant service covers all mechanical supporting and auxiliary components and systems. From deaerators and vacuum systems to water treatment skids and Delas’ check valves, proper and regular maintenance are key to prolonging life and ensure safety.