For more than 50 years we have engineered, commissioned, and delivered or retrofitted hundreds of condensers.

-

Performance & reliability

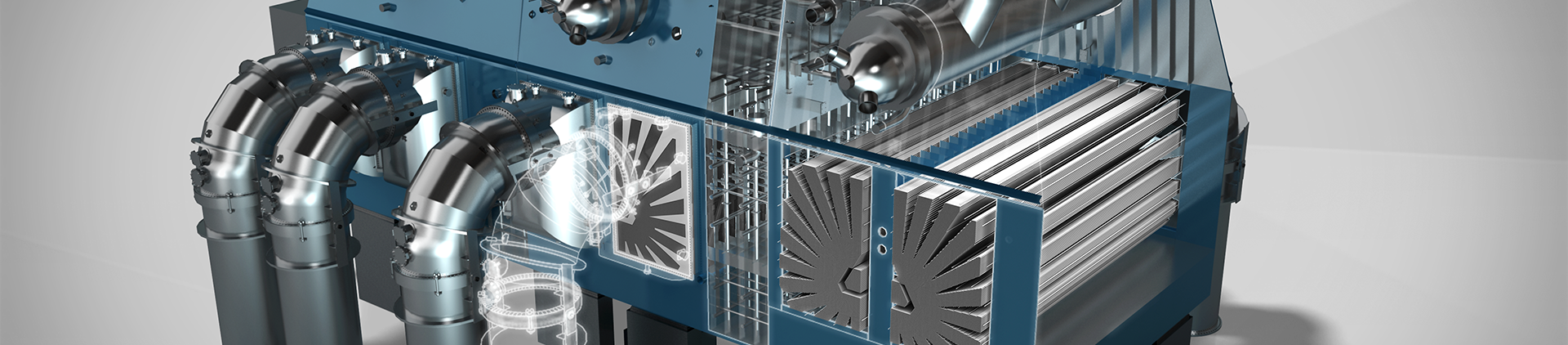

Patented tube bundle design and track record of outstanding performance.

-

Efficiency

Includes highly efficient tube bundles that meet the needs of any size power plant.

-

Robust design

Designed to handle turbine and steam generator overloads and variations in cooling water temperature.

Meeting specific requirements

Our condensers are designed for each specific installation, meeting high-performance requirements, enhancing reliability, adapting to varied site cooling conditions, and providing simplified construction with pre-assembled modules. They are resistant to both impingement erosion and tube vibration.

The condensers are delivered as fully tubed modules, so that little welding is required on site, they house the first two stages of low-pressure heaters for simplified arrangement of the turbine building.

The range of surface condenser types comprises rectangular and cylindrical design, in underslung and floor-mounted arrangement, applying single- and multi-pressure technology, both for PWR and BWR power plants.

Condenser solutions

| Typical Reference Solutions for: | 1,000 MW | 1,200 MW | 1,700 MW |

|---|---|---|---|

| Condenser Vacuum Type | Single | Dual | Single |

| Condenser Thermal Load (MW) | 1,820 | 2,030 | 2,750 |

| Absolute Pressure at Turbine/Condenser Connection (mbar abs) | 55 | 52/70 | 35 |

| Max Condensate O2 Content at 100 % Load (ppm) | 20 | 20 | 10 |

| Circulating Water | - | - | - |

| Circulating Water Temperature Design (°C) | 25 | 22 | 13 |

| Circulating Water Nature | Seawater, Once-through | Fresh Water, Cooling Towers | Seawater, Once-through |

| Circulating Water Flow (m3/s) | 63 | 40 | 60 |

| Circulating Water Temperature Rise (°C) | 7 | 6 \6 | 11 |

| Tubes | - | - | - |

| Exchange Surface (m2) | 76,000 | 70,000 | 115,000 |

| Material | Titanium | Stainless Steel | Titanium |

| Length (m) | 16.5 | 15 | 15.5 |

| Tube to Tubesheet Joint | Expanded/Welded | Expanded/Welded | Expanded/Welded |

| Weights | - | - | - |

| Operation (tons) | 2,200 | 3,450 | 5,800 |

| Water Filling (tons) | 3,600 | 4,600 | 9,700 |

| Dimensions | - | - | - |

| Hotwell Bottom to Turbine (m) | 13 | 16.5 | 14 |

Our MSR offerings

Our experience and technology can improve efficiency, raise performance, and extend the service life of your MSRs.