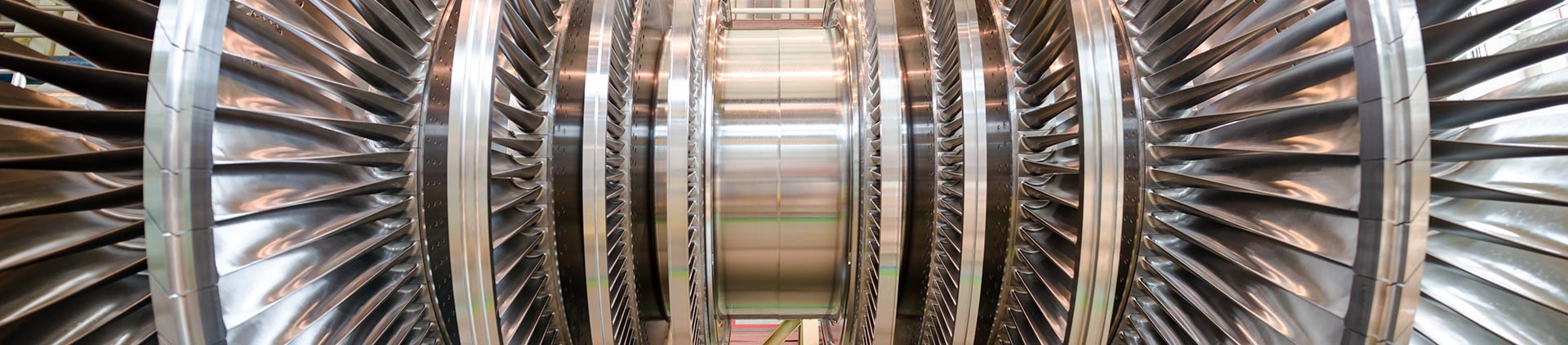

From the world’s most powerful steam turbine in operation to modular designs optimized for SMRs, our turbines are suitable for any reactor type from 50 MW to 1900 MW.

-

Increased efficiency

Our advanced 3D blading platform helps enhance the load grade and customize the flow path for project specific conditions and increased steam turbine performance.

-

High reliability

Advanced lifetime assessment procedures and long-term testing process increase our steam turbine reliability and availability.

-

Enhanced flexibility

Advanced fracture mechanic methods provide reliable lifetime assessment of the steam turbine components and increased cycling capabilities.

-

Full integration

Operational feedback is systematically applied across our entire modular turbine product portfolio to insure full integration.

Advanced steam turbine blading

Innovative blading technology is apparent in our:

- Modern, three-dimensional profile that results in higher steam power efficiency

- High pressure (HP), intermediate pressure (IP), and low pressure (LP) front stage blades that are milled from a single forging for excellent mechanical integrity and higher reliability

Deploying both impulse and reaction type blading technology to optimise performance and cost for maximum customer value.

Powerful last stage blades

Our enhanced last stage blade portfolio for steam turbines offers:

-

Dense staggered last stage blade sizes for project specific cold-end conditions and increased steam turbine efficiency

-

A robust module with enhanced grooves and blade attachments for higher turbine reliability

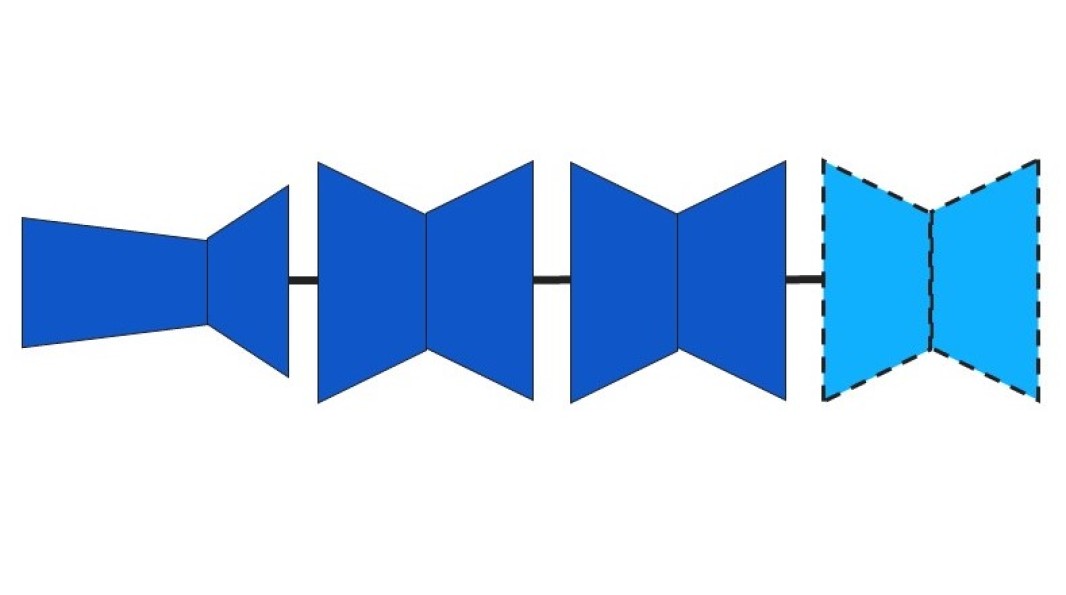

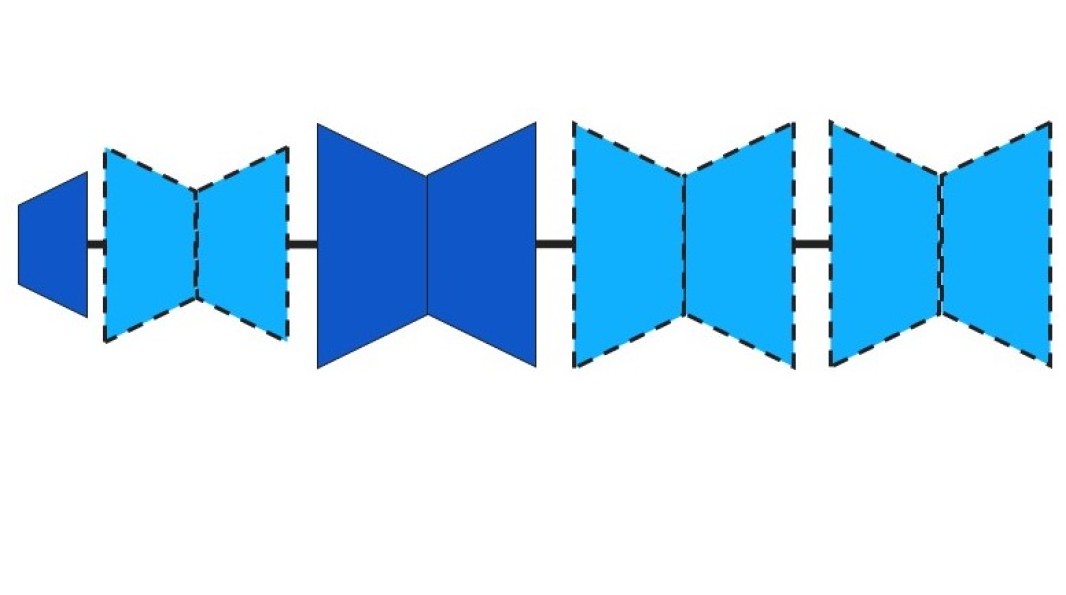

Single bearing efficiency

Our single bearing between each turbine module offers:

-

Avoidance of load shifting for higher reliability

-

Efficient shaft alignment for reduced construction time

-

Shorter overall turbine shaft length for lower building costs

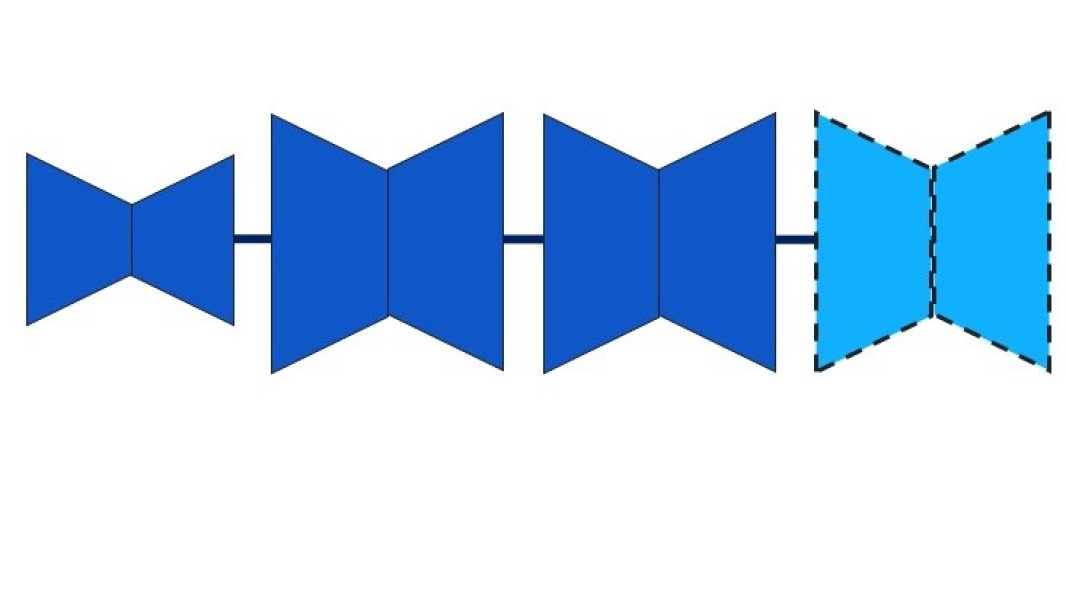

Welded rotor technology

Introduced in 1930, welded rotor technology can enhance the steam turbine lifetime

- Appropriate forging material selection, based on temperature level at each section of the steam turbine

- Stress reduction during thermal transients for faster and more frequent load cycling capability

- Better access for ultra-sonic testing equipment, resulting in higher reliability

Arabelle Solutions steam turbine portfolio

Arabelle 1000 & 1700

Our highly efficient flagship turbine range, suiting all reactor types from 700 to 1,300 MW and 1,200 to 1,900 MW respectively.

Learn more

STF-N700

The STF-N700 turbine offers robust architecture and cutting-edge blading technology adapted for any backpressure condition.

Learn more

STF-N100 to STF-N600

With a compact modular design, our portfolio of SMR turbines is suitable for reactors producing between 50 to 600 MW.

| Product | Application | Steam parameters | Output Range | |

|---|---|---|---|---|

| ARABELLE 1700 | half speed | Up to 75 bar/ 1090 psig, 300°C/ 570°F | 1,200 - 1,900 MW | |

| ARABELLE 1000 | half speed | Up to 75 bar/ 1090 psig, 300°C/ 570°F | 700 - 1,300 MW | |

| STF-N700 | full speed | Up to 75 bar/ 1090 psig, 300°C/ 570°F | 500 - 800 MW | |

| STF-N600 | full speed | Up to 300 bar/ 4350 psig, 630°C/ 1150°F | 350 - 600 MW | |

| STF-N400 | full speed | Up to 185 bar/ 2683 psig, 600°C/1112°F | 250 - 550 MW | |

| STF-N200 | full speed | Up to 185 bar/ 2683 psig, 600°C/ 1112°F | 100 - 350 MW | |

| STF-N100 | full speed | Up to 165 bar/ 2030 psig - 565°C/1050°F | 50 - 130 MW | |

Cyber Security

Arabelle Solutions steam turbines are protected by enhanced cyber security defences, designed to meet all major global and local cybersecurity standards and regulations. We apply a holistic multi-layer protection strategy, providing nuclear power plants with an up-to-date all-around cyber security solution.

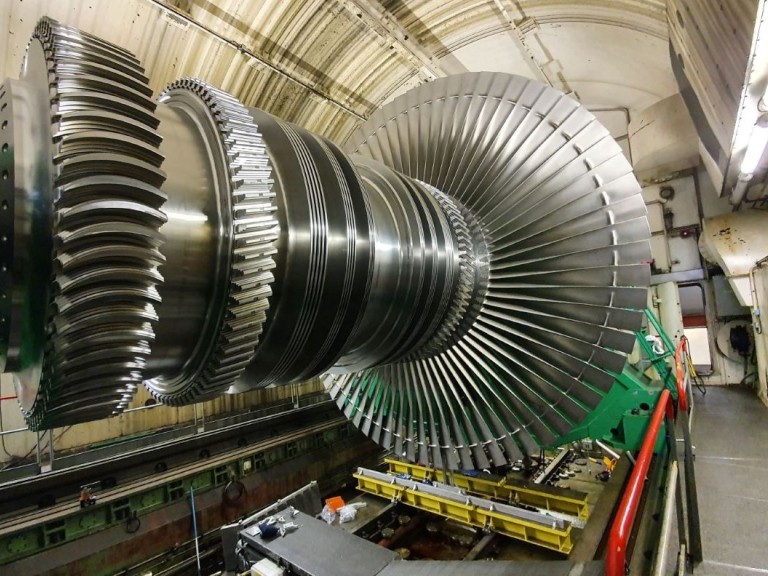

Our flagship Arabelle turbine

Suitable for large and very large reactors and with an impressive reliability record the Arabelle turbine is highly efficient, reliable, and effective.

The turbine suits power outputs ranging from 700 MW to 1,900 MW, making it the largest steam turbine in operation worldwide.