Save on maintenance costs and reduce outage durations with diagnostic technologies encompassing robotic inspections and health check of the stator core.

Preventing the unplanned

Successful generator maintenance means controlling the risk of failures and unplanned downtime by making smart decisions based on more accurate inspection and operational data.

-

Robotic inspection: Save on unnecessary downtime by enabling inspection of generator components without the removal of the rotor.

-

Pulsar testing: Data accuracy with lesser power consumption than high-voltage tests and fewer EHS risks.

-

Generator Health Monitoring: Digital monitoring to reduce the risks of unplanned events with condition-based maintenance.

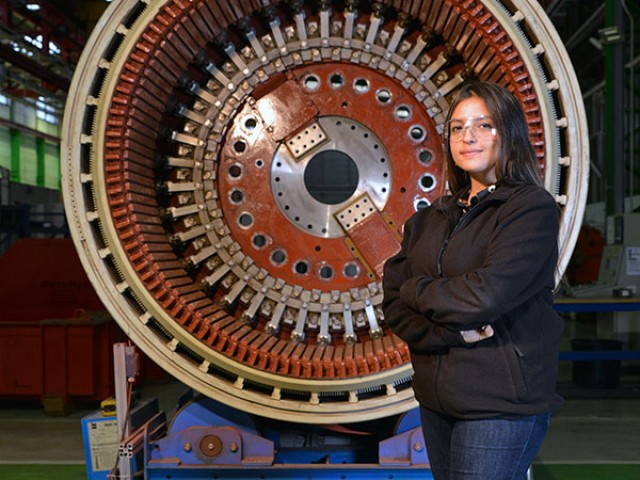

Robotic inspections

Robotic inspections save unnecessary downtime by enabling inspection of generator components without removal of the rotor.

Robotics package includes rotor-in-place inspection with small robots, a precision tool that sends probes through air gaps to conduct critical testing of the generator components, as well as the retaining ring scanner.

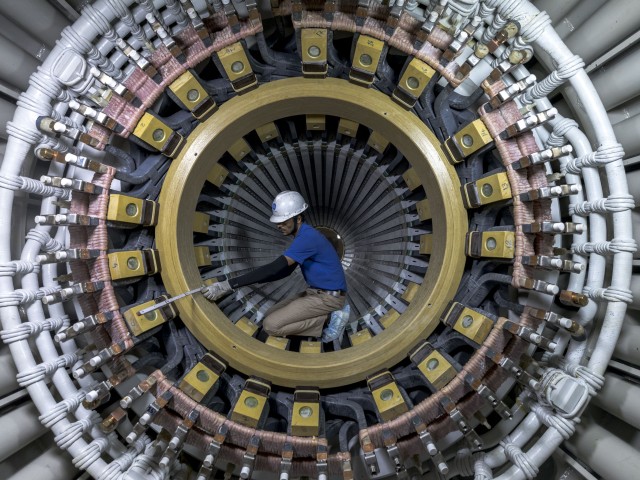

- As robots slide into the tight air gap between the rotor and stator, they record a video of the stator bore surface and the rotor body surface to look for signs of deterioration, such as delamination of the core packets, and check for signs of contamination. They also detect stator-core short circuits which, if undetected and not corrected, can lead to core burning and the need for costly, time-consuming repairs.

- Robots’ wedge-tightness probe flags the necessary fix of stator slot wedges. The scanning of retaining rings will allow the detection of stress corrosion cracking on inner and outer surfaces.

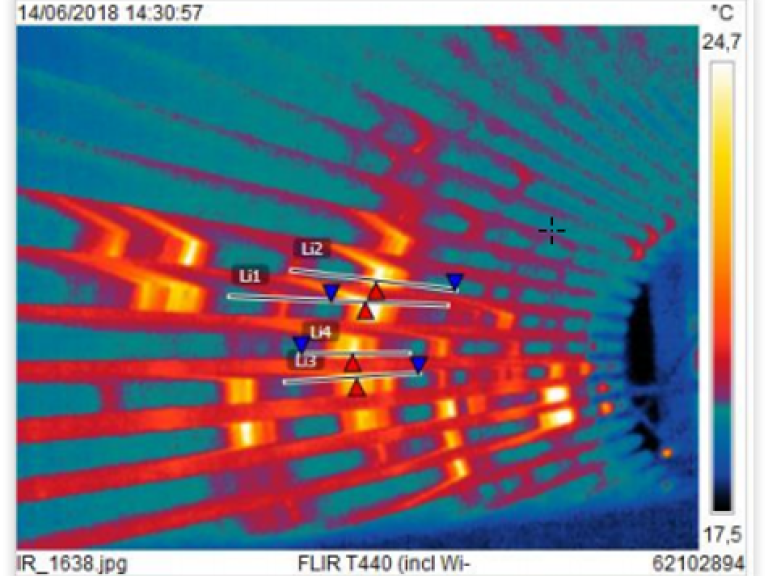

Stator core testing with Pulsar

The health check of a stator core is a routine test carried out during rotor-out inspections. Common testing methods like ELCID and HVRF tests can take long to carry out, adding safety challenges, costly logistics, and sometimes with challenging data (defects-detection and localization).

Pulsar is the alternative method that offers data accuracy, lesser power consumption than high-voltage tests, available power supply source (400 V), and fewer EHS risks (no high-voltage cables).

Our teams have been performing over 50 Pulsar tests since 2016. These tests are suitable for generators between 40-1650 MVA across all cooling conditions.

Generator Health Monitoring

Benefit from our digital and remote Generator Health Monitoring solutions to develop the future condition-based maintenance of your generators. We have a range of monitoring modules to better control the most critical areas of the generators, which can detect early failure modes to better anticipate your future maintenance planning.