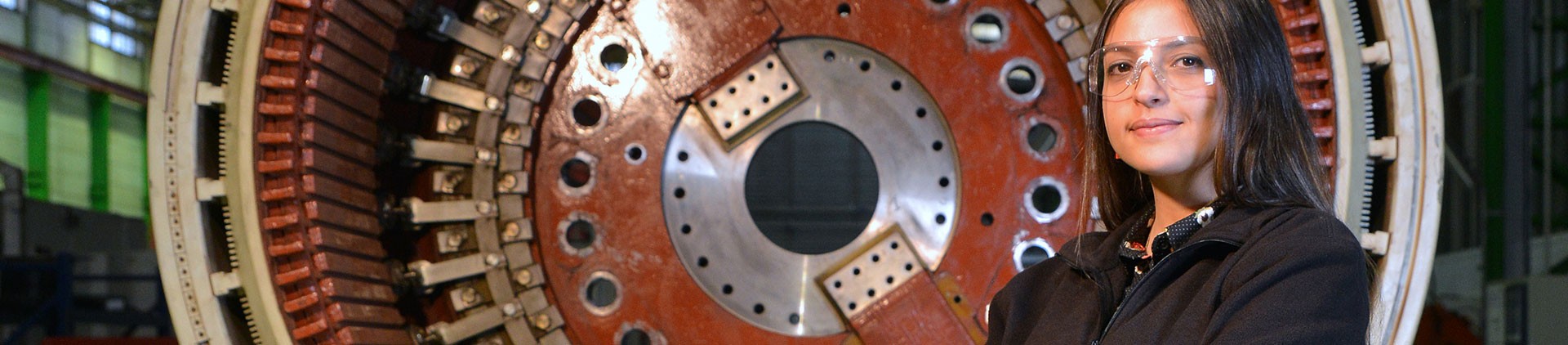

Experience with dozens of successfully executed rewinds across a wide range of nuclear reactor generators. Our rewind solutions include unique, proven technologies and processes, addressing aging issues of stator windings.

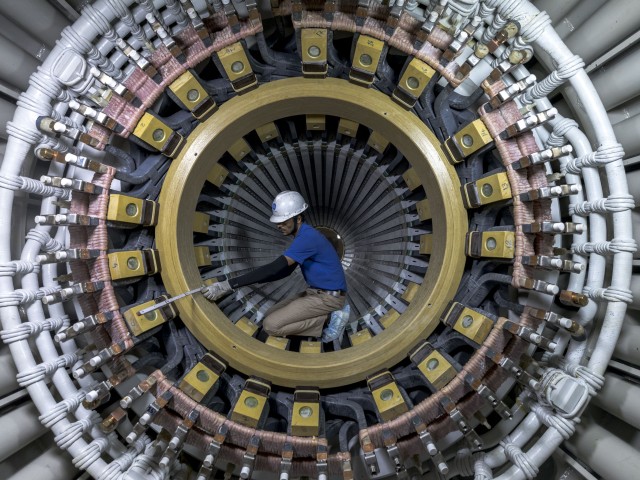

Generator rotor rewinds

Experience shows that the rotor is often the generator component requiring the most maintenance. With an ageing fleet of generators in operation worldwide, it’s important to take steps to extend unit lifetime and maintain reliability.

Based on decades of rewind experience on own and other manufacturer equipment, Arabelle Solutions can provide a wide range of tailored rewind services across Europe, Asian and Africa, delivering a shorter downtime with high-quality and reliability.

Reliable and effective stator rewind services

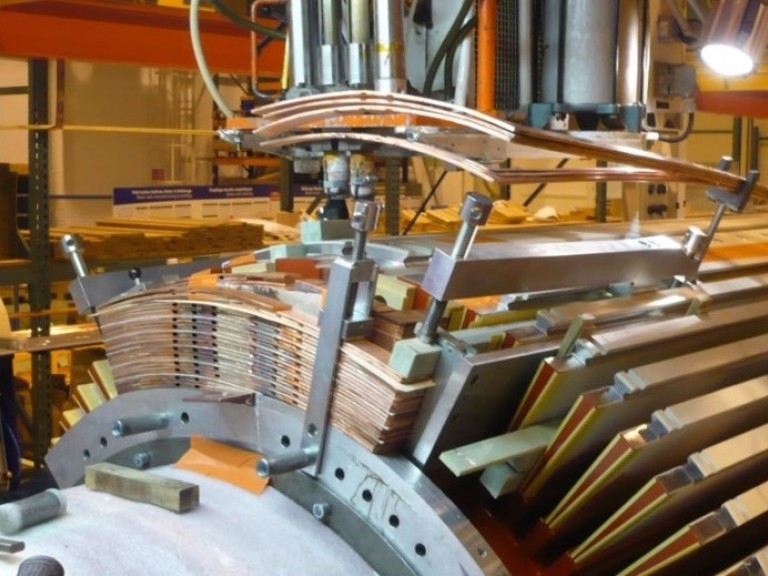

Arabelle Solutions' stator rewind services are standardized approach based on our deep, diverse generator heritage and knowledge. Stator Rewind services are a package of four modules: measurement, engineering, bar manufacturing, and onsite rewind.

Our proprietary processes and tools have been developed for quick, flexible execution with a focus on quality control at every stage.

-

Proven and reliable technologies and processes, applicable to both OEM and other OEM generators

-

Regional capabilities for faster mobilization supported by global expertise

-

Onsite stator rewind integrated into a major turbine outage for minimal operational disruption

Stator rewind features

- Stainless Steel stator bars for large liquid-cooled rewinds

- Stainless cooling tubes

- Tig weld connections between steel tubes and the water chamber

- Mechanical bolted connections between the stator bars and Teflon hoses

- Stator slot wedging technologies used and proven for decades

- Digital applications help integrate processes from measurement onsite to field service execution.

Stator rewind benefits

- Braze-free stator bar hydraulic circuit reduces the possibility of water leaks due to crevice corrosion

- Pre-assembled end winding basket reduces installation cycle time

- Provide the Option to re-use existing winding basket (contingent upon the material status)

- Stainless steel technology that is less sensitive to cooling water chemistry (oxygen content, Ph) and variations in chemistry