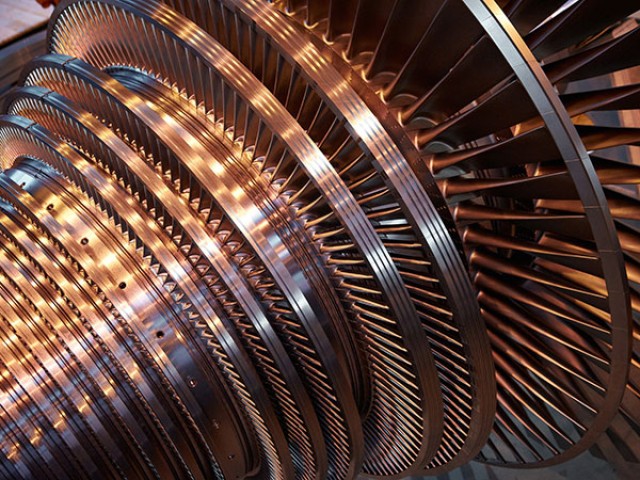

Arabelle Solutions' steam turbine life extension and upgrades service provide the capability and flexibility for an extended operational lifecycle.

Nuclear power plants are frequently required to operate in ways that differ from their original concepts and have their life cycle extended. We can customize solutions to increase the output, extend asset life or enhance operational flexibility.

LP Monoblock Rotor benefits:

'Built-up' rotors can experience stress corrosion cracking (SCC) in nuclear environments. Our LP Monoblock rotor and section upgrades can increase the turbine reliability.

- Significantly reduces SCC susceptibility in the wheel dovetails

- Reduces rotor in-service inspection scope due to boreless rotor

- Improves output and heat rate for units with the 43-inch L-0, resulting in up to 1% improvement in output.

LP section upgrade benefits:

- Significantly reduces SCC issues through new low-stress dovetail configuration.

- Improves turbine output and heat rate:

- 38- to 43-inch L-0 stage bucket delivers up to 4.5% in output improvement

- L-0 stage bucket delivers up to 3.5% in output improvement

- Delivers reduced inspection requirements and an extended rotor inspection interval of 10 years.

Valve life extensions and replacements

Arabelle Solutions has a wealth of experience in upgrading valves on many fleets and machine types. The most common way to achieve significant benefits is to upgrade the parts to improved, modern technologies.